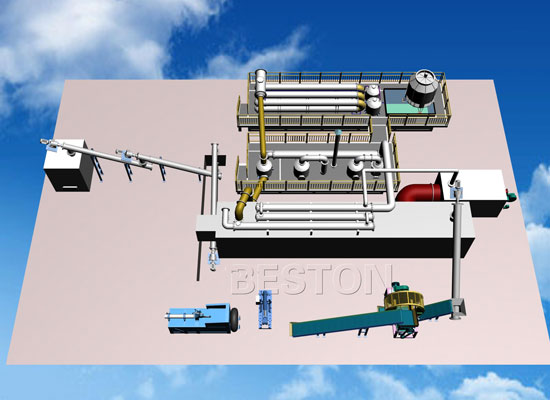

Waste products can accumulate at your business no matter kind of industry you are in. Therefore, it is important you buy continuous plastic pyrolysis plant for working on these waste products. Continuous waste plastic pyrolysis plant applicable raw materials include polystyrene, polypropylene and polythene just to mention but a few. The final product when of continuous waste plastic pyrolysis process will be carbon black and fuel oil. The entire waste pyrolysis equipment for sale is controlled by programmable logic controller. So it is very easy to control and operate it and our customers can save on labor and time.

The following are main features of continuous waste plastic pyrolysis plant

Long working hours

During the process which is referred to continuous pyrolysis process, the reactor is heated too much by indirect hot air. You find that this hot air does not damage the reactor at thus it keeps the reactors for use for long time. Contact waste to energy equipment manufacturer to know the accurate working hours.

Fully automatic

When you buy continuous waste plastic pyrolysis plant you will realize it is fully automatic with little labour cost input. The system as mentioned earlier is controlled by PLC with automatic feeding and discharge which only needs a computer or a maximum of two people to control it.

Large capacity

Due to the continuous feeding and discharge that the system is subjected to, you find that it has multiple reactor design units. Thus, you will find that when you buy continuous waste to energy machine from us, it has at least ten tons waste plastic per day. This is a big capacity for a machine to handle, in fact it is beyond the minimum threshold per say. Besides, we also have small pyrolysis machine for sale. See the waste tyre pyrolyis plant UK.

Fully pyrolysis for high oil plant

You will also realize that when you buy continuous waste plastic pyrolysis plant from us it adapt to multiple reactor design. This makes fully pyrolysis to mention of waste plastics giving a very high oil output in the end.

Internal rotating for continuous operation

When you buy continuous waste plastic pyrolysis plant you will realize that you need to change the sealing material of the external rotating system after three days. Therefore, it cannot achieve the intended continuous process in the real sense. But our continuous waste plastic pyrolysis plant machines reactor adapts to the internal rotating method. Thus, there is no need to worry about the external rotating system at all. This phenomenon of continuous work in process saves time and energy in the long run.

Buy continuous pyrolysis equipment from us and get to enjoy diverse raw materials that can be used including plastic, waste tires and also rubber. It is important to mention that the execution of this machine plant technology can be done with only a little amount of investment cost, short recovery period, high availability of the required raw materials and a promising bright future ahead, is the real and ideal choice for investment. Fuel oil which is derived from this waste plastic pyrolysis plant project report is in a very big demand across the world nowadays. To buy continuous waste plastic pyrolysis plant get in touch with us and you will get the best machine installed for you.