Maximizing operational efficiency and profitability is central to the sustainable success of amusement venues. With rising maintenance costs, competitive pricing pressures, and evolving guest expectations, ride operators and investors must strategically balance throughput, resource optimization, and guest satisfaction. Every element—mechanical reliability, queue logistics, energy consumption, and seasonal adaptability—plays a role in boosting return on investment.

Profitability in amusement equipment depends on multiple interlocking factors: high uptime, minimal operational friction, and optimized guest flow. This means eliminating performance bottlenecks, automating monitoring systems, and adapting ride configurations to match demographic demands.

Predictive Maintenance and Downtime Reduction

Downtime remains one of the most significant barriers to profitability. To reduce ride interruptions, operators should adopt predictive maintenance protocols. Unlike reactive repairs, predictive systems use real-time sensors and telemetry data to monitor component wear, motor temperature, and vibration anomalies. This enables technicians to intervene before a failure occurs, extending asset life while minimizing service disruption.

Cloud-based diagnostic platforms now provide centralized dashboards to track the health of multiple rides across a park or chain. Integration with maintenance management systems allows for automated scheduling of inspections, part replacements, and compliance documentation—cutting labor costs and improving operational continuity.

Modular Design and Interchangeable Components

Modular ride design supports operational agility. Amusement equipment with interchangeable cabins, decorative panels, or lighting systems allows for rapid theming shifts, seasonal rebranding, and easier component replacement. Such flexibility shortens refurbishment timelines and keeps experiences fresh for returning visitors.

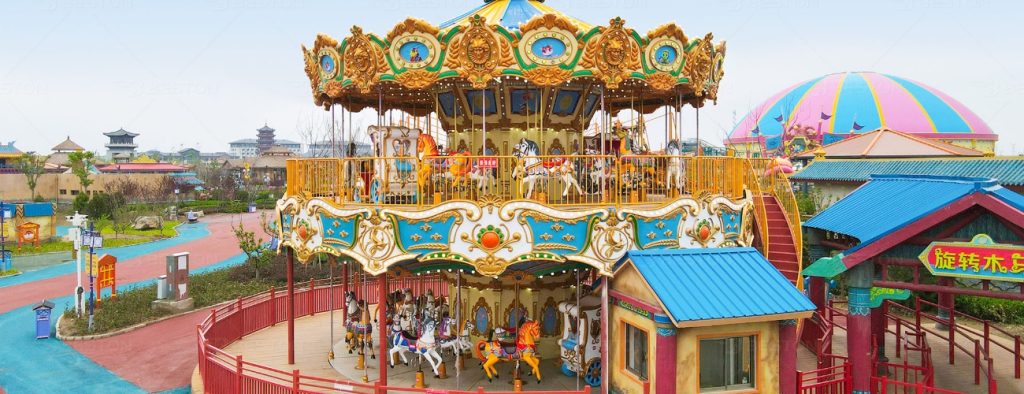

For instance, when evaluating a carousel for sale, operators should prioritize models that support interchangeable figures, programmable lighting, and sound upgrades. These allow the attraction to stay visually relevant and event-aligned without replacing the entire system—extending product relevance and monetization opportunities.

Queue Optimization and Throughput Management

One of the most overlooked drivers of profitability is ride throughput. Optimizing queue flow not only enhances guest satisfaction but also increases the number of ride cycles per hour. This can be achieved by improving loading/unloading procedures, utilizing dual-entry platforms, and adopting dynamic ride scheduling during high-traffic periods.

Digital queue systems, such as app-based reservations or timed tickets, further reduce congestion. They free guests to explore retail or food zones, increasing secondary spend. For larger attractions such as a pirate ship amusement ride, dual-gate boarding and automatic restraint checks can reduce turnaround time by 20–30%, significantly impacting daily yield.

Staff Allocation and Automation

Efficient staffing aligns team placement with traffic forecasts. Advanced scheduling tools use historical attendance patterns and weather forecasts to allocate operators dynamically. During low-volume periods, automation can reduce labor costs. Smart access control, RFID-based check-ins, and automated boarding signals can reduce the need for additional staff without compromising safety.

Where applicable, voice-guided operator interfaces can standardize safety checks and pre-ride instructions. This consistency enhances compliance and reduces variability caused by human error, while also speeding up loading processes.

Data-Driven Pricing and Yield Management

Dynamic pricing strategies can help capture more value during peak periods and incentivize traffic during off-peak times. By analyzing attendance trends, ride popularity, and weather data, parks can implement variable ticketing systems for specific attractions. Time-based or package-based ticketing models can increase per-capita revenue without significantly altering operational costs.

Promotions linked to underutilized rides also help balance traffic. For operators looking to buy amusement rides, choosing systems with programmable cycle lengths and user-tier adaptability supports more granular control of capacity and pricing tiers, further enhancing flexibility.

Seasonal Adaptability and Theming

Adaptability is vital for extending operational lifespan. Seasonal overlays allow the same ride to serve different audience segments throughout the year. For instance, a standard children’s ride can be retrofitted with themed elements for Halloween, winter festivals, or brand collaborations. This minimizes capital expenditure while boosting perceived novelty.

Investing in structural compatibility for overlays—magnetic signage, LED façade skins, or quick-mount props—makes seasonal adaptation more cost-effective. For revenue-intensive units like a 2 story carousel, upper deck access can be temporarily restricted during low traffic to reduce maintenance and operator requirements while retaining visual impact.

Revenue Diversification Around Core Rides

Each ride can become a revenue node, not just through ticketing but through experience bundling. Photo booths, themed merchandise kiosks, and adjacent food stands strategically placed near high-traffic rides increase average transaction values. Premium ride tiers—such as VIP gondolas or extended-ride experiences—create upsell pathways.

Larger installations can also be rented for private events. Offering birthday packages or branded experiences tied to iconic equipment—such as themed rides on a carousel for sale—adds incremental revenue while improving community engagement.

Energy Optimization and Environmental Cost Reduction

Energy-efficient systems reduce operational overhead. Variable-frequency drives (VFDs) on motors, LED-based lighting, and regenerative braking systems lower utility consumption while maintaining performance. Smart meters track and optimize power draw during operation and standby periods.

Sustainability can also be a marketing asset. Certifications in energy efficiency or eco-friendly materials can boost brand value and open access to green funding incentives. For new installations, choosing an amusement equipment manufacturer that specializes in low-energy, low-emission designs adds long-term financial value.

Lifecycle Planning and ROI Benchmarking

To ensure financial viability, operators should track cost per cycle, maintenance hours per 100 operating hours, and average revenue per seat per ride. Lifecycle analysis helps identify underperforming assets and supports investment planning. Rides approaching end-of-life can either be refurbished with new theming or relocated to less competitive locations.

Before committing to new purchases, conducting a ride compatibility audit ensures that infrastructure—power supply, foundation, guest flow—is suitable. This reduces installation costs and shortens time-to-operation, accelerating revenue generation from day one.

Optimizing operational efficiency and profitability in amusement equipment management requires a systems-level approach. Through predictive maintenance, modular customization, smart staffing, and data-driven pricing, operators can achieve significant gains in output and margin. When supported by responsive theming and sustainability practices, each ride becomes a multi-dimensional asset—capable of engaging guests, reducing waste, and driving growth in an increasingly competitive market.