Is your neighbourhood struggling with old tires? If yes, a waste pyrolysis plant project is highly beneficial not only to your neighbourhood, but also to the environment and the economy. With the increasing challenge of scrap tyres associated with the increasing number of cars and bikes on the roads, the world is struggling to properly dispose of these scrap tires causing a serious environmental problem. In fact, due to lack of proper disposal mechanisms, a significant fraction of these used tyres are either burnt or dumped in various waste sites, which negatively affects the environment. Luckily, the tyre recycling pyrolysis project has now made it possible to end these harmful traditional disposal mechanisms.

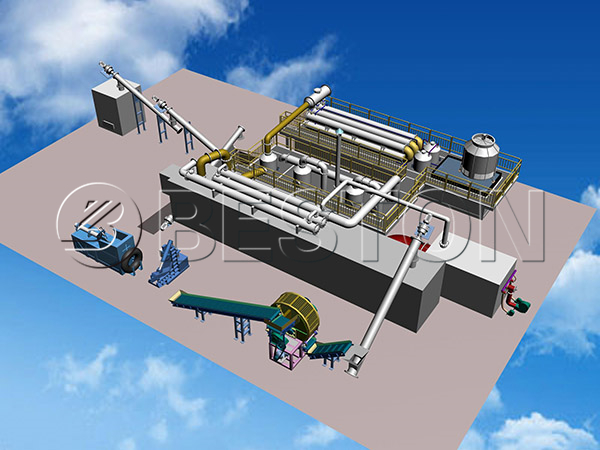

A tires to oil recycling pyrolysis project is a beneficial process that helps dispose of used tyres without the negative effects of traditional methods through tyre recycling. The process involves a thermo chemical decomposition of used tyres at higher temperatures in the absence of oxygen for usable final products. The tyre recycling pyrolysis project heats the shredded or whole tires in a reactor vessel that includes a heat source and an oxygen-free atmosphere to soften the rubber. The rubber polymers are then broken down into smaller molecules that eventually vaporize and exit the reactor. These exiting vapours can be condensed into an oily liquid or burned to produce power. Other molecules that are very small to condense remain as gas. The remaining part of the tire is then left as a solid. Besides, the cost Beston Machienry provides is competitive. More info: https://tyrepyrolysisplants.net/tire-recycling-plant-cost.html.

When properly done, a tyre recycling pyrolysis project has no waste. The solid left the process can be separated into various components such as carbon black and steel for different uses resulting in at least 90-percent tyre recycling success. Furthermore, there are no chemicals used in the process and thus, it is fully environmentally friendly. The process also does not cause any soil, water, or air pollution, unlike the traditional disposal methods. In addition to the environment benefit, a tyre recycling pyrolysis project also has an economic benefit. The waste products of the tyre recycling plant for sale that include fuel oil, carbon black, steel wire and waste gas are all industrial raw materials with a market value.

The fuel oil is the largest final product of a tyre recycling pyrolysis taking about 45 to 50 percent of the total waste. The fuel oil is widely used in industrial and commercial applications that range from chemical industries to gas venting systems as well as in the construction materials. Carbon black is the second highest component with about 30 to 35 percent of the total waste depending on the type of the tyre. Carbon black can be used as the main ingredient or as a raw material in various industries.